Powder Coating Troubleshooting Guide

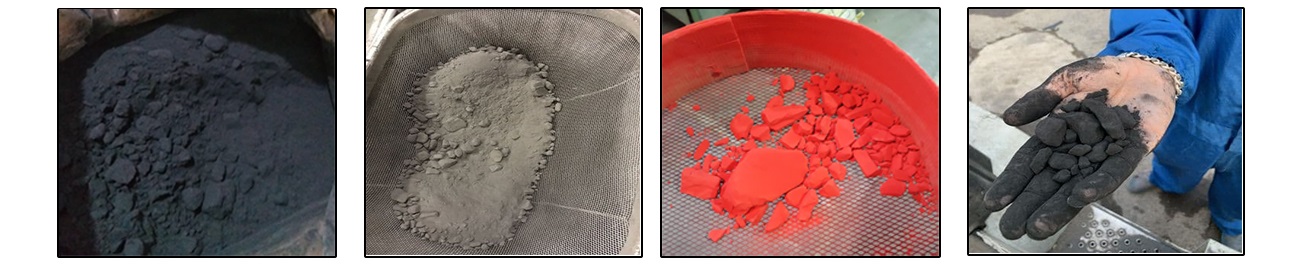

1- Unfavorable storage condition (High heat / humid area)

2- Storage has exceeded the shelf life of powder

1-1- Sift the powder using sieve number 200-300 microns

1-2- Check optimal powder storage conditions in technical data sheet

1-3- Store powder at less than 25 °C

2-1- Use a fresh batch of powder

1- Air Pressure is too low or too high

2- Powder settled at the hopper bottom (old powder or poor storage conditions)

3- Oil or moisture in compressed Air

4- Powder is moist or is too fine

5- Air channels of the flow plate are clogged

1-1- Control and adjust the air pressure

1-2- Replace hose or use a hose with larger diameter

1-3- Check air filtration system (filter, pipes and air) and make sure hoses or filters are not clogged

2-1- Stir the powder or sift it using sieve number 200-300 microns

2-2- Check optimal powder storage conditions in technical data sheet

2-3- Store powder at less than 25 °C

2-4- Use a fresh batch of powder

3-1- Check air for oil & moisture (Filters and Moisture Traps in the air system)

4-1- Increase virgin powder or change the powder

4-2- Check optimal powder storage conditions in technical data sheet

5-1- Empty the hopper, clean the pores of the fluidizing plate & if necessary replace the fluidizing plate

1- The hopper air pressure is high

2- The powder quantity is more than 3/4th of hopper capacity

3- Recycle to virgin powder ratio is more than recommended

1-1- Reduce the hopper inlet air pressure

2-1- Reduce powder quantity to 3/4th of the hopper capacity

3-1- Add virgin powder to hopper and always limit reclaimed powder up to 20%

1- Inappropriate hose material

2- Moisture or oil in compressed air

3- The air injector components are worn

4- Feed hose is too long or diameter is wrong

5- Air pressure is too low or too high compared to powder quantity

6- Inappropriate hose mounting

1-1- Replace hose with appropriate type (silicone, polyurethane etc.)

2-1- Check air for oil & moisture (Filters and Moisture Traps in the air system)

3-1- Replace nozzle

4-1- Adjust the length and the diameter of the hose appropriate for the powder flow

5-1- Reduce or increase the pressure according to powder quantity

6-1- Mount hoses properly to prevent kinking

1-1- Reduce reclaimed powder and/or increase virgin powder quantity

1-2- Clean the Spray gun regularly and more frequently

1-3- Sift the reclaimed powder before using

1- Unnecessary excessive opening of the paint booth doors

2- Clogged filters inside the paint booth

3- Excessive powder from the spray gun (more than standard)

1-1- Keep the spray booth doors closed

1-2- Switch and adjust inlet and outlet openings based on the size of parts being painted

2-1- Increase Spray booth ventilator suction

2-2- Clean filters and replace them if required

3-1- Reduce the number of guns or decrease the powder from the gun

1- Air velocity is too high causing the powder to disperse

2- Distance between gun and part is inadequate or improper painting technique

3- Powder feed is too high or too low

4- Poor or weak grounding

5- Spraying gun voltage is too low or too high

6- Improper Spray Equipment

7- Powder is too fine

1-1- Decrease the air pressure of spray gun

2-1- Adjust the distance between spraying gun and part (approximately 6 to 8 inches)

3-1- Adjust amount of powder from the spray gun

4-1- Check and secure ground (up to 1 megaohm)

5-1- Adjust voltage to have appropriate coverage in corners and to avoid repelling

6-1- Change spraying nozzle type to a smaller or flat nozzle

7-1- Increase virgin powder or decrease recycling powder

1- High film thickness

2- Powder is wet

3- Powder is contaminated with other materials

4- Part surface is too rough

5- Voltage is too high

6- Changes in the process of powder manufacturing

1-1- Decrease the paint thickness

2-1- Sift and dry the powder and decrease the ambient temperature of the paint system

3-1- Clean the hopper, paint booth and hoses again

4-1- Modify the cleaning and surface preparing procedure of the part

5-1- Reduce voltage

6-1- Consult with powder manufacturer and follow their recommendations

1- Poor charging of powder - The spray gun voltage is unnecessarily high

2- The spray gun and the parts are either too close or too far (gun to part distance is more or less than recommened)

3- Poor or weak earth connection

4- Time of the part in the booth is too short

5- Spray Booth airflow disrupts spraying - Inappropriate air humidity in the spray booth

6- The parts are complex in design or are not hung properly

7- Parts from dry off oven are too hot

8- Powder delivery hose is too long or clogged with powder deposits

9- Foreign particles (Cloth Fibers / Dust etc.) clogging the powder transport system

1-1- Test and adjust spray gun voltage

2-1- Adjust the distance between the gun and the part (standard distance is 6 to 8 inch)

3-1- Check and secure the earth connection

4-1- Reduce line speed, increase powder from the gun or increase the number of the guns in the spray booth

5-1- Test and adjust system configuration and contact spray booth supplier if necessary

6-1- Change the way parts are hung

6-2- Increase / Decrease gun to part distance

6-3- Change gun setting

7-1- Adjust dry off oven temperature or let the parts cool for longer

8-1- Make sure diameter and length of the hoses is proper and that there are no kinks

9-1- Cleaning and maintenance of the transport system should be regular and more frequent

1- Poor grounding

2- Voltage is too low / powder does not charge properly

3- Too much powder output from the gun

4- Powder is too fine or too coarse

5- Conveyor / Racks have too much vibration

1-1- Conveyor / Racks have too much vibration

2-1- Check the gun, cables and electrodes

2-2- Measure gun voltage and make sure the readings match on spraying equipment display

3-1- Reduce powder and / or air flow

4-1- Decrease the amount of the recycled powder (if applicable)

4-2- Contact powder manufacturer to consult about the appropriate powder gun

5-1- Check the system to prevent jerks and shocks to the parts

1- Film thickness is too low or too high

2- Parts do not heat up quickly (Heat up cycle is too slow)

3- Voltage or Air pressure is too high

4- Inappropriate painting technique

5- Contamination with other powders

1-1- Measure film thickness with a thickness gauge and make sure to follow recommendations of the paint manufacturer

2-1- Conduct oven profile (e.g. datapaq) and confirm recommended cure parameters

2-2- May consider preheating the heavy / thick parts

3-1- Adjust air pressure and voltage of the spray gun

4-1- Adjust gun to part distance

4-2- Train painter for gentle passes / strokes of powder

5-1- Clean booth, guns and hoses

5-2- Consult with powder coating manufacturer for incompatibilities

2- Over or under curing

1-1- Clean the coating booth, spraying gun and hoses properly before replacing with new powder

1-2- Avoid using powder coatings from multiple manufacturers in the oven at the same time

2-1- Follow powder coating manufacturer recommendations

2-2- Adjust the oven heat or time parts spend in the oven

3-1- Adjust oven temperature and the time parts spend in the oven

1- Film thickness is too low

2- Different substrates and / or colored materials

3- Faulty spray gun

4- Poor ground and / or Low Voltage

1-1- Follow manufacturers recommendations for film thickness range

2-1- Compare same substrates

2-2- Consult with powder coating manufacturer for similar hiding on all substrates

3-1- Contact spray gun manufacturer

4-1- Check and secure ground and increase voltage

1- Oven temperature is too low

2- The powder is contaminated with smooth powders in the hopper

3- Powder has expired

4- Storage conditions are not favorable

1-1- Adjust and increase the oven temperature per technical data sheet

2-1- Clean the hopper / paint booth and hoses of other powders

3-1- Check the expiration date

4-1- Check storage conditions (Temp and Humidity)

1- Over or under curing

2- Varying film thickness on different areas

3- Improper Oven Exhaust

4- Uneven color due to varying thickness of the parts

5- Paint booth is not properly cleaned of the previous color causing haziness or variation in color

6- Powder is too old or has expired

1-1- Follow Powder Coating manufacturer recommendations

1-2- Adjust the oven heat or time parts spend in the oven

2-1- Apply the powder to the surface evenly and follow manufacturers recommendations

3-1- Check for blockage of the exhaust

3-2- Make sure oven fan is working properly

4-1- Adjust oven temperature and the time parts spend in the oven

5-1- Clean the booth thoroughly before changing or adding new colors

6-1- Use a fresh batch of powder

1- Paint booth is not properly cleaned of the previous color and the contents are incompatible

2- Poor washing that left oil contaminants on the work piece

3- Moisture or oil in compressed air

4- Moisture on the work piece

5- Parts are rusty

6- Surrounding air is contaminated

7- Silicone from the lubricants or sprays

8- The part is porous and outgassing

9- In rough textures, pinholes appear instead of the rolling texture

1-1- Clean the paint booth properly before painting and with every color change

2-1- Test the washing system and make necessary adjustments (contact supplier)

3-1- Check the system for oil and moisture. Replace filters regularly

4-1- Increase dry off oven temperature or the time parts spend in the dry off oven

5-1- Make sure parts do not have rust before painting

5-2- Store parts inside the shop unless painted

5-3- Use mechanical pretreatment like sandblasting or buffing

6-1- Avoid using powder coatings from multiple manufacturers at the same time

6-2- Prevent cross air drafts

7-1- Use silicone free lubricants

8-1- Preheat and outgas's the parts before painting

8-2- Use outgas forgiving products

9-1- Increase film thickness (3.5 - 4.5 mils). Consult powder manufacturer

1- Contaminants from Oven, Booth or Conveyor system

2- Air pressure or voltage too low

3- Feed hose is too long or diameter is wrong

4- Oil and moisture in the compressor air

1-1- Check cleaning procedure and increase cleaning frequency

1-2- Check the paint line for dust contamination and burnout of furnace insulation etc.

3-1- Adjust air pressure and voltage of the spray gun

4-1- Use appropriate length and diameter for the hose

5-1- Check air and oil filters and assure regular replacement

1- Film thickness is too high

2- Undercuring

3- Inadequate or Incompatible cleaning or pretreatment

1-1- Lower the powder or reduce the number of guns to adjust the film thickness to 2.5 to 3.5 for smooth and 3.5 to 4.5 for textured finishes

2-1- Follow manufacturers recommendation. May need to run oven profile to determine suitable baking schedule based on the substrate and parts thickness

3-1- Test the washing system and make necessary adjustments (contact supplier)

1- Inadequate washing and / or poor surface preparation

2- Very High film thickness

3- Parts are rusty

4- Lack of adhesion between 2 coats (primer & topcoat for example)

1-1- Test the washing system and make necessary adjustments (contact supplier)

2-1- Adjust paint thickness based on Manufacturer Standard

3-1- Make sure parts do not have rust before painting

3-2- Store parts inside the shop unless painted

3-3- Use mechanical pretreatment like sandblasting or buffing

4-1- Half bake first coat, apply second coat and then fully bake afterwards

4-2- For heavy parts, preheat the parts and apply both coats back to back and then put in the oven for a final bake

1- Film thickness is too high

2- Substrate temperature is too high (causing a high film build)

3- Powder paint moves to the edges

4- Inappropriate curing conditions (Heat-up rate is too high)

5- Powder falls and accumulates at the bottom of the part

1-1- Decrease the powder from the gun to reduce film thickness

2-1- Increase cooling time between dry off and paint booth, Adjust film thickness as necessary

3-1- Check and secure ground and/or decrease the voltage

4-1- Adjust heat up speed. Check the oven and adjust temperature

5-1- Check and secure proper grounding